Izindlu zokuhlunga ezizihlanzayo zamanzi ezinensimbi engagqwali

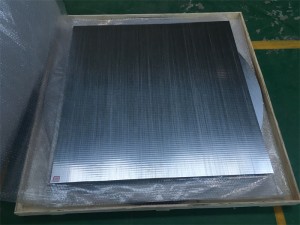

Isihlungi esizihlanzayo siphinde sibize isihlungi sezindlu/isistimu yokuhlunga, siqukethe umzimba oyi-cylindrical omile, isivalo sokuvala, i-flange, ipuleti yokuxhuma njll. ngaphakathi kungakhetha izinga lokuhlunga elihlukile lesici sokuhlunga. Indlela yokuxhuma ingase ibe izinhlobo eziningi zomumo njenge-bayonet nokuxhumeka kwentambo. Izinga lokuhlunga kanye nendlela yokuxhuma iyatholakala ngokuya ngezidingo zenqubo yamakhasimende. Izinto zokuhlunga yi-SUS304 ,SUS316L\Hastelloy alloy. Indawo yangaphakathi iyapholishwa, idlulwe uketshezi olune-asidi futhi ayikho i-engeli efile.

Umgomo wokusebenza kwesihlungi sokuzihlanza

Isihlungi sizoqala inqubo yokuhlanza lapho ukucindezela okuhlukile kokungena nokuphumayo kufinyelela kunani elisethiwe. Yonke inqubo yokuzihlanza iqukethe izinyathelo ezimbili: i-valve yokudonsa esembozweni sokugcina sesihlungi iyavuleka; amabhulashi amabili ensimbi engagqwali ku-ontology mesh ashayelwa yinjini ngaphakathi, khona-ke ukungcola okuthathwe ngamanetha kuzobhulashwa ngebhulashi lensimbi futhi kuzokhishwa ku-valve yokukhipha amanzi. Yonke inqubo yokuhlanza ithatha cishe imizuzwana eyi-15 kuya kwengama-60, Ngesikhathi kulokhu, isistimu yokuhlunga ayimi futhi yonke inqubo yokusebenza iqedwa ngebhokisi lokulawula.

Zuza

Vikela impilo nokuphepha kwabasebenzisi bakho - Ngesistimu evalwe ngokuphelele, awukho umkhiqizo oyingozi onjengentuthu ongaphuma ngenkathi futhi ukhawulela ukuchayeka ko-opharetha kwemikhiqizo yakho ewuketshezi.

Khulisa amanani akho okukhiqiza - Ngomklamo wayo wokuzihlanza akukho okumisiwe ukushintsha imidiya yokuhlunga, okuholela ekuhlungeni okungaguquki nokuthembekile.

Thuthukisa ikhwalithi yomkhiqizo wakho - Uhlelo oluvaliwe luqeda ubungozi bokungcola okungena kulayini wakho wokukhiqiza.

Yehlisa udoti kanye nezindleko zokusebenza - Isihlungi esizihlanzayo siqeda isidingo sokushintsha imidiya yokuhlunga kanye nezindleko zokulahla, ukunciphisa ukumoshwa komkhiqizo, izindleko zabasebenzi kanye nesikhathi sokuphumula.

isicelo

1. Insimbi: isetshenziselwa ukuhlunga amanzi endaweni eluhlaza, isitshalo se-sintering pellet, ukuhlunga kwamanzi okupholisa kwesithando somlilo esiqhumayo, umshini wokugaya, umshini wokuphonsa oqhubekayo nezinye izinhlelo, kanye nokuhlunga kokungcola kwesistimu yokususwa kwe-phosphorus yamanzi.

2. Izimoto: imigqa yokukhiqiza enamathelayo isetshenziswa kakhulu ezinhlelweni zokuhlanza amanzi ezimotweni, ogandaganda, izithuthuthu, nezinjini.

3. Imboni yamandla: Isetshenziselwa ukunemba kwengxenye yokulungiswa kwamanzi ahlanzekile kakhulu ama-boilers wezitshalo zamandla, ukuhlungwa kwamanzi okupholisa i-generator namanzi okuvalwa, kanye nesistimu 13-4 ingasetshenziswa njengesihlungi esiseceleni lapho amanzi ukusetshenziswa kukhulu ngokwedlulele.

4. Imboni ye-petrochemical: endaweni ejikelezayo yamanzi yokwelashwa kokuhlunga ohlangothini, amamodeli angashadile noma amaningi angaxhunywa ngokufana ukuze aphathwe ngokuyinhloko esikhundleni sokuhlunga impahla yokuhlunga, ukunciphisa umthwalo wokuhlunga impahla, ukugwema inani elikhulu lokugeza amanzi okusetshenziswa kanye nezindleko zokulondoloza. .

5. Izingadi zezolimo kanye nezigayo zephepha: Ezifafazweni nasezinhlelweni ze-nozzle, ukuvaleka kwemishini nokuguga okubangelwa ukungcola kufanele kuncishiswe. Ngakho-ke, kuyadingeka ukukhetha ukunemba okuphezulu, imikhiqizo yokuhlunga ezenzakalelayo ephezulu, imishini, ukudla noma okunye: Ukuhlunga okuzenzakalelayo nokunembile ukuvimbela ukuvala uhlelo lwamanzi okupholisa.

| Amapharamitha ajwayelekile wesihlungi sokuhlanza ngokwakho | |

| Izinga lokugeleza kokusebenza | 20-5000m3/hIkhwalithi yamanzi ehlukile nokunemba kwesihlungi kunezinga lokugeleza elihlukile elenziwe ngokwezifiso |

| Ingcindezi yokusebenza | I-2bar-10barBooster futha imishini ingasethwa endaweni yokukhipha amanzi lapho ingcindezi yokusebenza iphansi. |

| Usayizi we-valve yokukhipha | 25mm; 50mm; 80mm |

| Isikhathi sokuhlanza | 30-60S |

| Ukuhlanza ukusetshenziswa kwamanzi (njalo) | ≤5% |