Ifektri yokuhlunga yesikhwama sezindlu eqondile yezindlu

incazelo emfushane:

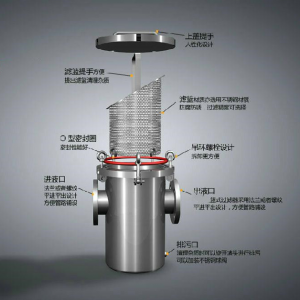

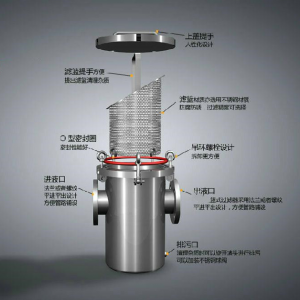

Isihlungi sesikhwama siwuhlobo lwemishini yokuhlunga enezinjongo eziningi enesakhiwo senoveli, ivolumu encane, ukusebenza okulula nokuvumelana nezimo, ukonga amandla, ukusebenza kahle okuphezulu, umsebenzi ongangenisi nomoya oqinile. Isihlungi sesikhwama siwuhlobo lwedivayisi yokuhlunga ingcindezi, ikakhulukazi eyakhiwe izingxenye ezintathu: isitsha sokuhlunga, isikhwama esisekela inetha kanye nesikhwama sokuhlunga. Lapho isihlungi sesikhwama sisetshenziselwa ukuhlunga uketshezi, uketshezi lungena lusuka endaweni ewuketshezi oluseceleni noma ngezansi kwesiqukathi sokuhlunga, bese lugijimela esikhwameni sokuhlunga lusuka phezulu kwesikhwama sokuhlunga esisekelwe yinethi eluhlaza okwesibhakabhaka. Isikhwama sokuhlunga siyanwetshwa ngenxa yomthelela we-liquid kanye ne-uniform pressure surface, ukuze izinto eziwuketshezi zisatshalaliswe ngokulinganayo endaweni engaphakathi yesikhwama sonke sokuhlunga, futhi uketshezi oludlula esikhwameni sokuhlunga luhambisana nenetha lokusekela lensimbi. blue wall. Ikhishwa endaweni ephuma kuyo ngaphansi kwesihlungi. Izinhlayiya ezihlungiwe zivaleleke esikhwameni sokuhlunga ukuze kuqedelwe inqubo yokuhlunga. Ukuze ugcine isihlungi sibushelelezi futhi sinembile futhi uqinisekise ukuthi uketshezi olungaphansi komfula alungcoliswanga, umshini kufanele uvalwe ngemva kwesikhathi sokusebenza, ikhava yokugcina yesihlungi kufanele ivulwe, udaba olunqanyuliwe kanye nesikhwama sokuhlunga kufanele sivuleke. zikhishwe ndawonye, futhi isikhwama esisha sokuhlunga kufanele sishintshwe. Isikhathi sokushintsha sincike esimweni sangempela. Ukunemba kwesihlungi okuhlukile kuncike ezikhwameni zokuhlunga ezihlukene.

Impahla: SS304; 316; 316L, carbon steel

Ukwelashwa kwendawo: ukupholishwa kwesibuko, ukuqhunyiswa kwesihlabathi, njll.

Ngenisa futhi uthumele ifomu: i-flange, ukukhweza okusheshayo, intambo.

Okunye ukucaciswa kungenziwa ngezifiso.

Izinga lokugeleza kwethiyori yinani eliyireferensi lokwelashwa kwamanzi. Inani langempela lizohluka nge-viscosity, okuqukethwe kokungcola kanye nomehluko wengcindezi yoketshezi.

Izici zomkhiqizo:

Isihlungi se-1.Bag sinezinzuzo zomthamo omkhulu, umthamo omncane kanye nomthamo omkhulu.

I-2.Ngokusekelwe kumgomo wokusebenza kanye nesakhiwo sesistimu yokuhlunga isikhwama, kulula futhi kuyashesha ukufaka esikhundleni sesikhwama sokuhlunga, futhi isihlungi asinakho ukuhlanza, ukonga umsebenzi nesikhathi.

I-3.Izinga lokuvuza ohlangothini lwesikhwama sokuhlunga lincane, eliqinisekisa ngokuphumelelayo ikhwalithi yokuhlunga.

I-4.Isihlungi sesikhwama singathwala ingcindezi yokusebenza eyengeziwe, ngokulahlekelwa kwengcindezi encane, izindleko eziphansi zokusebenza kanye nomphumela osobala wokonga amandla.

I-5.Ukunemba kokuhlunga kwesikhwama sokuhlunga kuye kwathuthukiswa ngokuqhubekayo, futhi manje sekufinyelele ku-0.5um.

I-6.Isikhwama sokuhlunga singasetshenziswa ngokuphindaphindiwe ngemva kokuhlanza ukuze kugcinwe izindleko.

Isihlungi se-7.Bag sinezinhlobonhlobo zezinhlelo zokusebenza, ukusetshenziswa okuguquguqukayo kanye nendlela yokufaka ehlukahlukene.

Ububanzi besicelo:

Isetshenziswa kakhulu emshinini wokugaya uketshezi lokugaya, okokunamathela, upende, ubhiya, uwoyela wemifino, umuthi, amakhemikhali, izimonyo, imikhiqizo kaphethiloli, amakhemikhali endwangu, amakhemikhali azwelayo, isixazululo se-electroplating, ubisi, amanzi amaminerali, i-hot flux, i-latex, amanzi ezimboni, ushukela, inhlaka, uyinki, ijusi yezithelo, amafutha adliwayo, i-wax nezinye izimboni.

Imininingwane Yomkhiqizo

Omaka bomkhiqizo

Umkhiqizo izigaba

-

ubhasikidi strainer ubhasikidi isihlungi izindlu experienc...

-

Insimbi engagqwali 10micron isihlungi sezindlu isikhwama fil...

-

Isikhwama sensimbi engagqwali isihlungi sezindlu isikhwama cartridg...

-

Isihlungi Sesihlungi Sensimbi Engenasici esingu-70 seMicron...

-

Isihlunu se-sea water filtration housing basket strainer cu...

-

I-Candle Cluster Filterhousing Chemical Precision...