Insimbi engagqwali engu-10micron yokuhlunga isikhwama sezindlu isihlungi sezindlu ifektri eqondile

Izindlu zokuhlunga isikhwama wuhlobo lwemishini yokuhlunga enezinjongo eziningi enesakhiwo senoveli, ivolumu encane, ukusebenza okulula nokuguquguqukayo, ukonga amandla, ukusebenza kahle okuphezulu, umsebenzi ovaliwe nokusebenza okuqinile.

Ukucaciswa:

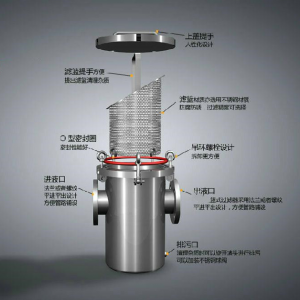

Izindlu zokuhlunga isikhwama wuhlobo lwedivayisi yokuhlunga ingcindezi, ikakhulukazi eyakhiwe izingxenye ezintathu: isitsha sokuhlunga, isikhwama esisekela inetha nesihlungi.

| Imodeli | I-HKV65-1 |

| Izingxenye | Isilinda sokuhlunga, ikhava, indlela yokuvula ngokushesha, isikhwama sokuhlunga esiqinisa anezikhala |

| Izinga lokuhlunga elincane | 0.5 μM |

| Ukwelashwa kwendawo | ukupholisha isibuko, ukuqhunyiswa kwesihlabathi, njll |

| Ngenisa futhi uthumele ifomu | i-flange, ukukhweza okusheshayo, intambo |

| Imininingwane ingenziwa ngezifiso | |

Isimiso sokusebenza

Izindlu zokuhlunga isikhwama wuhlobo lwedivayisi yokuhlunga uhlobo lwengcindezi. I-filtrate igeleza ingene esikhwameni sokuhlunga ngepayipi eliseceleni lokungena legobolondo lesihlungi. Isikhwama sokuhlunga ngokwaso sifakwe kubhasikidi wokuqinisa. I-filtrate efanelekayo ingatholakala lapho uketshezi lungena ngesikhwama sokuhlunga sebanga elidingekayo le-fineness, futhi izinhlayiya zokungcola zivinjelwe isikhwama sokuhlunga Sika. Kulula kakhulu ukushintsha isikhwama sokuhlunga, futhi akukho ukusetshenziswa kwezinto ezibonakalayo.

ukusebenza kanye nezinyathelo zokuphepha

Ukusebenza okulula. Uma isetshenziswa, idinga kuphela ukufaka isikhwama sokuhlunga sebanga elidingekayo le-fineness ku-cartridge yesihlungi, ihlole ukuthi i-O-ring isesimweni esihle yini, bese uqinisa ibhawudi lendandatho yekhava yekhatriji yesihlungi ukuze iqalise ukusebenza.

Ngemva kokuqala iphampu, igeji yokucindezela kusihlungi ikhuphuka kancane, futhi ingcindezi yokuqala icishe ibe ngu-0.05Mpa. Ngokunwetshwa kwesikhathi sesevisi, izinsalela zokuhlunga kusilinda zikhula kancane kancane. Lapho ingcindezi ifinyelela ku-0.4MPa, ikhava yesilinda kufanele ivulwe ukuze kuhlolwe izinsalela esikhwameni sokuhlunga, futhi isikhwama sokuhlunga singashintshwa ukuze siqhubeke nokusebenzisa (isikhwama sokuhlunga singasetshenziswa kabusha ngemva kokuhlanza).

Ingcindezi yokuhlunga ngokuvamile ilungiswa ku-0.1-0.3mpa, engalungiswa ngepayipi lokubuya noma i-valve yokubuyisela epompo. Uma ukucindezela kwesihlungi kuphezulu kakhulu, kuzolimaza isikhwama sokuhlunga kanye nenetha lokuvikela, ngakho-ke ukunakekelwa okukhethekile kufanele kukhokhwe.

Inzuzo yezindlu zokuhlunga isikhwama

I-1.amathuba amancane okuvuza ohlangothini lwesikhwama sokuhlunga mancane, okuqinisekisa ngokuphumelelayo ikhwalithi yokuhlunga.

Izindlu zokuhlunga ze-2.Bag zingathwala ingcindezi yokusebenza eyengeziwe, ngokulahleka kwengcindezi encane, izindleko eziphansi zokusebenza kanye nomphumela osobala wokonga amandla.

3.Izinga lokuhlunga elithuthukisiwe eliqhubekayo, selifinyelele ku-0.5 μ M manje.

4. Umthamo omkhulu, umthamo omncane kanye nomthamo omkhulu.

I-5.Kulula futhi kuyashesha ukufaka esikhundleni sesikhwama sokuhlunga, futhi isihlungi sikhululekile ukuhlanza, ukonga umsebenzi nesikhathi.

6.Ukusetshenziswa okuphindaphindiwe, izindleko zingagcinwa.

7. ububanzi bezinhlelo zokusebenza, ukusetshenziswa okuguquguqukayo kanye nezindlela ezihlukahlukene zokufaka.

Ububanzi besicelo:

Izindlu zokuhlunga zisetshenziswa kakhulu emshinini wokugaya uketshezi lokugaya, ukugqoka, upende, ubhiya, uwoyela wemifino, umuthi, amakhemikhali, izimonyo, imikhiqizo ye-petroleum, amakhemikhali ezindwangu, amakhemikhali azwelayo, isixazululo se-electroplating, ubisi, amanzi amaminerali, i-hot flux, i-latex, amanzi ezimboni. , ushukela, inhlaka, uyinki, ijusi yezithelo, amafutha adliwayo, i-wax nezinye izimboni.

Ukucaciswa:

Isihlungi sesikhwama siwuhlobo lwedivayisi yokuhlunga ingcindezi, ikakhulukazi eyakhiwe izingxenye ezintathu: isitsha sokuhlunga, isikhwama esisekela inetha kanye nesikhwama sokuhlunga.