I-cartridge yesihlungi sebhasikidi yensimbi engagqwali eyenziwe ngokwezifiso yokuhlunga kwezinhlayiyana zoketshezi lwezimboni

I-cartridge yesikhwama se-stainless steel stainless steel isihlungi se-strainer se-industrial liquid particle

Hlunga impahla yomzimba:A3,3014,316,316L

Ububanzi/ingcindezi: DN15-400mm(1/2-16″), PN0.6-1.6MPa

I-Nut&bolt:20#,304,316,316L

I-gasket yokuvala:NBR,PTFE,metal

Indawo yokubeka uphawu: ejwayelekile noma eyenziwe ngokwezifiso

Uhlobo lwe-conncetion: intambo yangaphakathi ye-flange, intambo yangaphandle, ikhadi elisheshayo

Izinga lokushisa lokusebenza:carbon steel:-30℃-+350℃,SS _80℃-+480℃

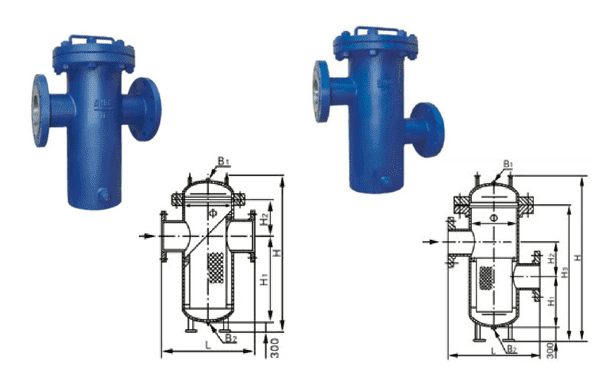

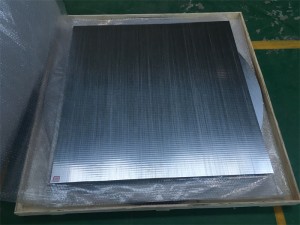

isihlungi sikabhasikidi

1. Isihlungi sikabhasikidi siyisisetshenziswa esibalulekile ukuze uchungechunge lwamapayipi ludlulise okuphakathi, futhi ngokuvamile lufakwa ohlangothini lwevalvu yokunciphisa ukucindezela, ivalvu yokukhulula, ivalve yokulawula izinga noma i-inlet yezinye izinto zokusebenza.

2.Isetshenziselwa ukuhlunga ukungcola okuphakathi ukuze kuqinisekiswe ukusetshenziswa okuvamile kwe-valve kanye nemishini.

Isihlungi se-3.basket sinesakhiwo esithuthukisiwe, ukumelana okuncane nokukhishwa kokungcola okulula.

Isakhiwo sesihlungi sikabhasikidi nendlela yokusebenza

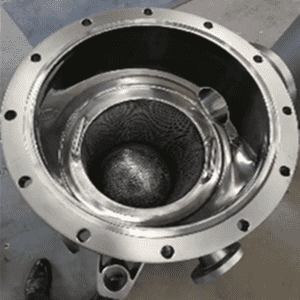

Isihlungi sikabhasikidi siqukethe ipayipi elixhumayo, ipayipi elikhulu, ubhasikidi wesihlungi, i-flange, isembozo se-flange kanye nezinsimbi.

Uma uketshezi lungena kubhasikidi okuhlungayo ngepayipi elikhulu, ukungcola kwezinhlayiyana kuzovaleleka kubhasikidi. Uketshezi oluhlanzekile luzongena kubhasikidi wokuhlunga bese luphuma lapho luphuma khona. Uma ludinga ukuhlanzwa, vula ipulaki yesikulufu kubhasikidi wokuhlunga. phansi kwepayipi elikhulu ngokuzungeza, khipha uketshezi. Khipha ikhava ye-flange, ubhasikidi ungafakwa epayipini elikhulu ukuze liphinde lisetshenziswe futhi. Ngakho-ke ukusetshenziswa nokugcinwa kulula kakhulu.

Ipharamitha ye-Basket Filiter Technical

| DN | Ububanzi besilinda (mm) | Ubude (mm) | Ubude-C (mm) |

Ubude-B (mm) |

Ubude-A (mm) |

I-Sewage Outlet |

| 25 | 89 | 220 | 360 | 260 | 160 | 1/2” |

| 32 | 89 | 220 | 370 | 270 | 165 | 1/2” |

| 40 | 114 | 280 | 400 | 300 | 180 | 1/2” |

| 50 | 114 | 280 | 400 | 300 | 180 | 1/2” |

| 65 | 140 | 330 | 460 | 350 | 220 | 1/2” |

| 80 | 168 | 340 | 510 | 400 | 260 | 1/2” |

| 100 | 219 | 420 | 580 | 470 | 310 | 1/2” |

| 150 | 273 | 500 | 730 | 620 | 430 | 1/2” |

| 200 | 325 | 560 | 900 | 780 | 530 | 1/2” |

| 250 | 426 | 660 | 1050 | 930 | 640 | 3/4” |

| 300 | 478 | 750 | 1350 | 1200 | 840 | 3/4” |

Isicelo

1.Imboni esebenzayo:Imboni yamakhemikhali emihle,isistimu yokwelapha amanzi,ukwenza iphepha,imboni yezimoto,i-petrochemical,ukucubungula ngomshini, ukunamathela nokunye.

2.Uketshezi olusebenzayo:Lonke uhlobo loketshezi olunezinhlayiya ezincane.

Umsebenzi oyinhloko wokuhlunga: Khipha inhlayiya enkulu, hlanza uketshezi futhi uvikele imishini eyinhloko.

3.Uhlobo lokuhlunga:Ukuhlunga kwezinhlayiya ezinkulu.Kusebenzisa isihlungi esisebenziseka kabusha.Kufanele sihlanzwe njalo ngemanuwali.

Ukugcinwa kwesihlungi sebhasikidi

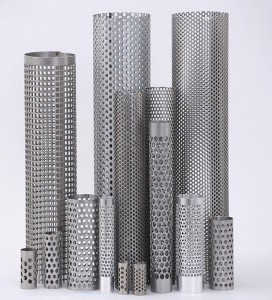

- Ingxenye eyinhloko yalolu hlobo lwesihlungi umgogodla wesihlungi.Ingxenye yesihlungi iqukethe ifremu yesihlungi kanye nensimbi engenasici.I-SS wire mesh ingeyezingxenye ezigugile.Idinga isivikelo esikhethekile.

- Ngemva kokuba isihlungi sisebenze isikhathi esithile, sizokwengeza inani elithile lokungcola kumongo wesihlungi.Khona-ke ukucindezela kuzokwenyuka futhi nesivinini sokugeleza sizoncishiswa.Ngakho kufanele sihlanze ukungcola okuphakathi kwesihlungi kusenesikhathi.

- Uma sihlanza ukungcola, kufanele siqikelele ukuthi siqinisekisa ukuthi i-SS wire mesh kumongo wesihlungi ngeke yonakale noma yonakale. Ngaphandle kwalokho, lapho usebenzisa kabusha isihlungi, ukungcola koketshezi oluhlungiwe ngeke kufinyelele imfuneko eklanyelwe. Futhi ama-compressor, ipompo noma izinsimbi zizobhujiswa.

- Uma i-SS wire mesh itholakele ikhubazekile noma ilimele, kufanele siyishintshe ngokushesha.